解析回流焊炉温测试步骤及注意事项

回流焊炉温测试方法有两种,一种是回流焊本身自带的温度测试功能,还有一种是炉温测试仪,相对于回流焊本身的测试功能,炉温测试仪更为精准,使用广泛。下面深圳欧海科技就和大家分享一下回流焊炉温测试步骤及注意事项。

一、正确设置回流焊炉温,每个工厂有自己的一套标准,不同机型有相应的要求,将测温板与炉温测试仪正确的进行连接,然后打开炉温测试仪的开关,将炉温测试仪放在防高温不锈钢盒内或高温保护套内。

二、然后将炉温测试仪连同测温板放进回流焊炉内,过炉的方式有两种,可以从轨道上过需用到合适的托架,也可以从网链上过直接平放在网链上即可,到回流焊后出板的位置等待取出炉温测试仪。

三、取出炉温测试仪后,将炉温测试仪与电脑正确连接,读取炉温数据,确认OK后打印炉温曲线表。如果炉温曲线不符合要求,则重新调试再重新测试回流焊炉温,直到读出来的数据与要求相符方可生产。

回流焊炉温测试注意事项:

在测试回流焊炉温之前需确认炉温测试仪测试是否正常,检查电池是否电量充足;在正常贴片过回流焊过程中,需不定时检查回流焊炉温,在测试回流焊炉温时,需确认回流焊轨道内是否有PCBA,以免造成品质事故;如果客户有要求测量IC或QFP温度时,要将电热偶线连接在IC引脚上;如客户要求测量BGA温度时,需在测试板正面的BGA焊盘处位置上钻一个孔,把电热偶线从测试板反面插入焊接到BGA焊点上,同时将整个BGA焊接在测试板上;如需测量手焊元件温度,要将电热偶线从正面穿过焊孔,伸出测试板的长度为1.5到2mm以便接触到锡波;在测试过程中需注意安全,防止高温烫伤。

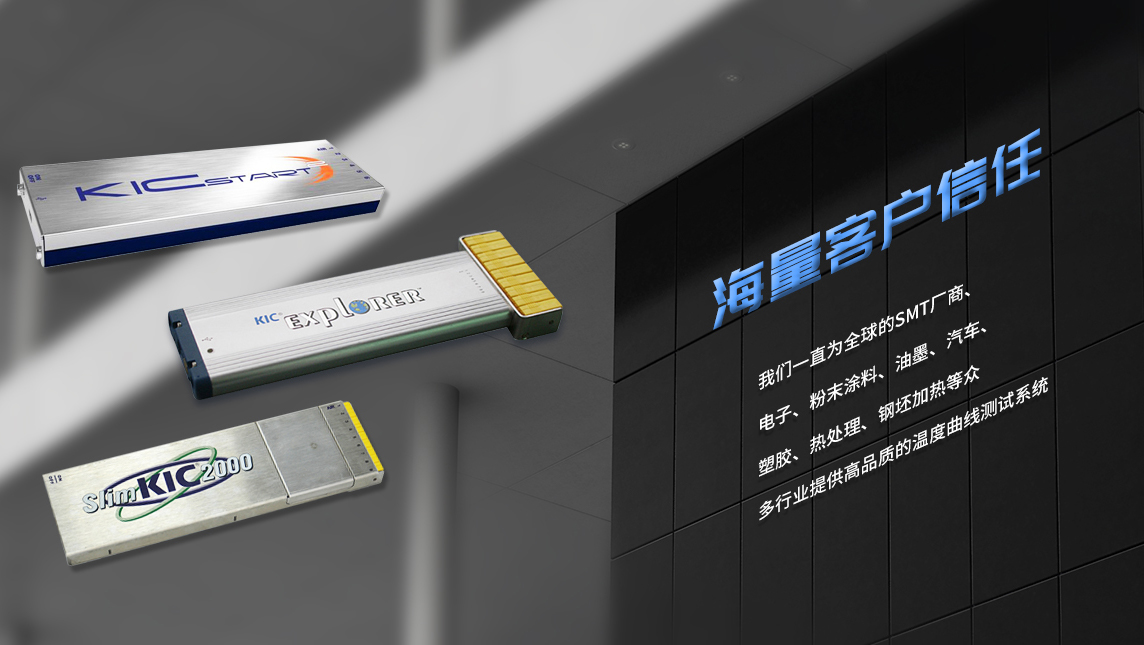

杭州欧海自动化设备有限公司是从事KIC炉温测试仪、回流焊炉温仪,炉温跟踪的业界实力派,我们在SMT、电子、粉末涂料、油墨、汽车、塑胶、热处理、钢坯加热等众多行业拥有丰富的实战经验。

公司自成立以来,现已成为温度测量和分析系统的有影响的企业。在高温炉温测试仪优先域中,已经并将继续推出准确、易用、长寿命的系统。我们在高精度的数据记录器、坚固可靠的隔热箱以及易用的分析软件三者的结合方面,我们精益求精,可带给您更大化的价值。目前已有成千上万的炉温跟踪系统正在世界各地被广泛使用。欢迎广大新来前来咨询购买

Analysis of reflow soldering furnace temperature test steps and precautions

There are two kinds of reflow oven temperature test methods, one is the temperature test function of reflow soldering itself, and the other is the oven temperature tester. Compared with the test function of reflow soldering itself, the oven temperature tester is more accurate and widely used. Next, Shenzhen Ouhai technology will share with you the reflow oven temperature test steps and precautions.

1、 To set the reflow soldering furnace temperature correctly, each factory has its own set of standards, and different models have corresponding requirements. Connect the temperature measuring plate with the furnace temperature tester correctly, then turn on the switch of the furnace temperature tester, and put the furnace temperature tester in the high temperature stainless steel box or high temperature protective sheath.

2、 Then put the furnace temperature tester together with the temperature measuring plate into the reflow soldering furnace. There are two ways to pass through the furnace. You can pass through the rail with a suitable bracket, or you can pass through the mesh chain and directly lay it flat on the mesh chain. Wait for the furnace temperature tester to be taken out at the position of the plate after reflow soldering.

3、 After taking out the furnace temperature tester, connect the furnace temperature tester with the computer correctly, read the furnace temperature data, and print the furnace temperature curve table after confirming that it is OK. If the furnace temperature curve does not meet the requirements, re debug and re test the reflow soldering furnace temperature until the data read out is consistent with the requirements.

Precautions for reflow oven temperature test:

Before testing the reflow oven temperature, it is necessary to confirm whether the oven temperature tester tests normally and check whether the battery is fully charged; during the normal reflow soldering process, it is necessary to check the reflow oven temperature from time to time. When testing the reflow oven temperature, it is necessary to confirm whether there is PCBA in the reflow soldering track, so as to avoid causing quality accidents; if the customer has the requirement to measure the IC or QFP temperature, it is necessary to connect the thermocouple wire Connect to the IC pin; if the customer requires to measure the BGA temperature, drill a hole in the BGA pad on the front of the test board, insert and weld the thermocouple wire from the back of the test board to the BGA Solder joint, and weld the whole BGA on the test board at the same time; if the temperature of the hand soldering component needs to be measured, put the thermocouple wire through the solder hole from the front, and extend the length of the test board for 1.5 to 2mm for contact In the process of testing, pay attention to safety to prevent high temperature scald.